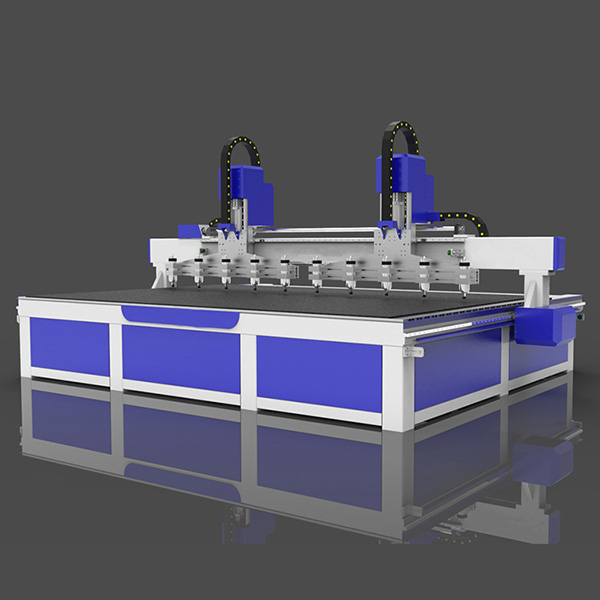

A necessary trick to prolong the life of CNC Routers equipment in winter

Hazards of using CNC Routers in low-temperature conditions in winter:1. The electric box is easy to cause condensation and frost in the low-temperature environment.2. At low temperature, movable electrical cables, movable cables in equipment drag chains and plastic (rubber) dust suction pipes becom......

Send Inquiry

Product Description

Hazards of using CNC Routers in low-temperature conditions in winter:

1. The electric box is easy to cause condensation and frost in the low-temperature environment.

2. At low temperature, movable electrical cables, movable cables in equipment drag chains and plastic (rubber) dust suction pipes become hard and brittle, easily broken and cause

Leakage phenomenon.

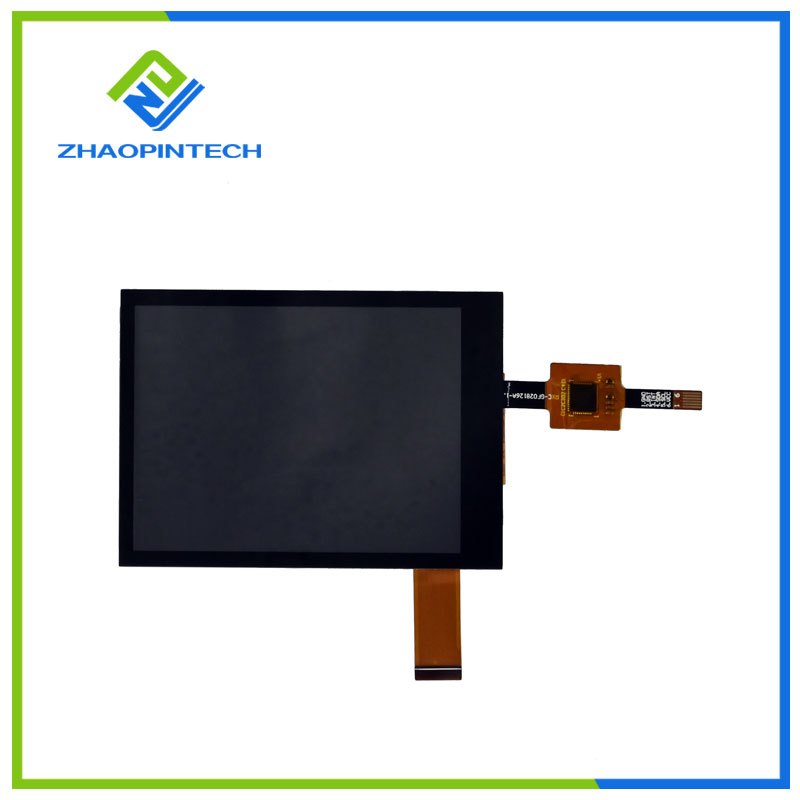

3. The capacitive screen and LCD screen of the equipment are prone to failure and malfunction at low temperatures.

4. When the programmable controller on the equipment (such as: indoor PLC and its modules) is used below 0°C, it is easy to cause failure, alarm, or damage to the module.

5. If the industrial computer on the device is used in a low-temperature environment, the system will restart, causing damage to the device.

6. The water in the filter of the air source processing component is easy to cause freezing and cracking of the filter, and the freezing of water inside the cylinder and solenoid valve causes work delay.

7. The water stored in the pressure gauges, flowmeters, traps, etc. of each pipeline freezes, causing damage to the sealing of the damaged components, causing water and air leakage.

8. The moisture in the water-cooled spindle or vacuum pump freezes, causing the cooling pipe to burst.

9. The quality of glued workpiece glue is reduced.

10. The physical and chemical properties of production raw materials and auxiliary materials change due to low temperature.

The following measures should be taken in response to the above problems:

1. The temperature of the CNC routers environment should be kept above 5°C, and the recommended temperature for edge banding and thermoplastic process workshops should be above 15°C. Attention should also be paid to the ambient temperature of raw material storage.

Prevent material denaturation.

2. The inspection should be strengthened to check whether the plastic and rubber of the suction pipe are deformed and cracked to cause leakage. Seal the places where condensation and frost have been found.

3. In cold weather in winter, start the main power supply of the equipment for 5 minutes before starting the control power supply, so that the air conditioner in the electric box can fully play its role.

4. Check the filter and drying system of the air source to prevent moisture from entering the air system of the equipment. Pneumatic three originals strengthen function detection to avoid failure.

5. The low ambient temperature of the central lubrication system may cause false alarms due to the increase in oil viscosity, and the original value must be recorded before adjustment is necessary. When the ambient temperature rises, the

Restore value.

6. Spindle or vacuum pump with water cooling should be added with specified antifreeze according to the requirements to avoid freezing and cracking of cooling pipes;

Drain part of the water.

7. The warehouse of raw and auxiliary materials shall set the appropriate storage temperature according to the data provided by the raw material supplier.